Finishing

Alpha Packagings offering of

Paper, Coating, Finishes & Embellishments

The unboxing experience is a delight in itself, and often it’s not so much about the product in the box as it’s about the first impression of the packaging. There is something special about opening a new box, and our perception of the brand is highly impacted by the visuals of the packaging.

Scroll through the page to see how our multiple laminates, coatings and extra options can help your packaging stand out as premium, win the hearts of your customers for good and bring you profit.

Alpha Packagings story starts with

Quality Paperboard

At the core of our business is the paper from which all our products are made. Without a quality paper, we wouldn’t be able to offer a finished product that matches the highest expectations. Being a renewable source, we feel it is our duty to take care of the finite resources nature provides. We have a profound respect for human rights to renewable fiber, originating from sustainably managed forests. This is why we have strategically chosen a paperboard supplier that is committed to the sustainability of our environment.

We have invested millions in machinery and technologies that allow us to take the most of what the paper offers and minimize waste. All our production waste is recycled weekly, making our recycling process very efficient and very eco-friendly.

Four trees are being planted for every tree that is cut to produce our paper.

14pt White Board

Premium SBS paperboard, sustainably produced

16pt White Board

Premium SBS paperboard, sustainably produced

18pt Brown Kraft Board

Ecological using 100% post-consumer recycled material

20pt Metallized Board

An extra silver substrate makes any colors shine

A protective layer using our

Coatings And Laminates

Coating and laminates are post-print processes that involve applying “film” laminates or liquid coatings that change the look and feel of the finished product. Some coatings and laminates can be combined with other extras, such as gold foil, embossing or debossing, to make a truly unique box.

In general, coating and laminates also increase the strength of the packaging and provide extra protection to scratches, abrasion or manipulation.

Gloss Laminate

Gloss Laminate is a film that is applied to the box after printing. It’s a very slick and shiny finish, making the colors pop more. The surface very smooth and reflects light.

Gloss Laminate adds thickness and strength to the box. It can be embossed, debossed and foil stamped.

Gloss UV Coating

The Gloss Ultra-violet (UV) coating is a liquid coating applied over printed paperboard and dried through a UV radiation process.

It’s the perfect choice if your product needs better protection from external factors, such as sun rays or humidity. It can be embossed, debossed and foil stamped.

Matte Laminate

The Matte Laminate will give a shine-free, smooth surface to your box. The matte finish is very luxurious and the soft feel can be combined with embossing, debossing, foil stamping, and spot gloss.

The matte finishes we offer are scuff-proof matte and soft-touch matte.

Scuff Proof Laminate

Is a very durable laminate, the strongest and most scuff-resistant laminate we offer. It gives a very soft sheen, but not a full true matte finish.

Scuff proof laminate add extra thickness and strength to the box. It can be embossed, debossed, foiled stamped and spot gloss coated.

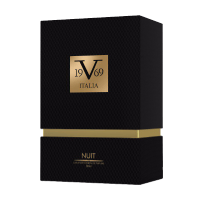

Soft Touch Laminate

This laminate is ideal for high-class skincare or cosmetic boxes. It has a true matte finish, very soft to the touch, and it encourages the customer to feel the box and interact with it.

Soft Touch is ideal for high-class skincare or cosmetic boxes. It adds strength to the box, and it can be embossed, debossed, foil stamped and spot gloss coated.

Spot Gloss Coating

Spot Gloss coating is a post-print technique in which gloss coating is applied using heat and pressure to a designated area of your box.

It makes the coated area “pop off” the paperboard with a glossy finish in direct contrast with the rest of the paperboard, color and graphics.

Upgrading the perceived quality

Using Our Extra Option

While most packaging can look incredible without adding extra embellishments, there is no doubt that paying attention to little details such as the much-appreciated gold foil or a embossing logo can go a long way into increasing the perception of your brand.

Packaging drives sales, and a investing a bit more in your packaging at first can help increase the perceived brand value of your products and secure your spot as a professional in your field.

Foil Stamping

This the process of applying a “foil” onto the box using a heated metal die and a press. When the die is applied to the surface, the foil bonds to the surface, producing the metallic foil effect.

It looks best when used to emphasize a logo or a design element. It can be combined with embossing to create a more striking 3D image.

Embossing

Embossing is a post-print technique that creates a tridimensional raised pattern on your box. It is made by placing an embossing die in contact with the paperboard under high heat and pressure.

It is often used to highlight the logos or specific elements of the brand on the box, making the box very interesting to the touch and giving it a very luxurious feel.

Debossing

Debossing is a post-print technique that creates a tridimensional depressed (or lowered) pattern on your box. It is made by placing a debossing die in contact with the paperboard under high heat and pressure.

It can be combined with embossing, hot foil stamping and different coatings if you want to offer your customers a full tactile experience.

Making An Informed Choice

Foil Stamp Vs. Metallic Paper

Although very similarly looking, there are important differences between foil stamping and printing on metallic paper. There are very different outcomes you can get by using one of the other. In this short section we’ve put together some of the benefits and drawbacks for each option to help you decide which will work best for your project.

Foil Stamping

This the process of applying a “foil” onto the box using a heated metal die and a press. The die is heated up, and the foil is placed between the die and the surface of the paper or other material to be stamped.

When the die is applied to the surface, the foil bonds to the surface, producing the metallic effect.

Pros

Cons

- Metallic “Leaf” Look

- “Shiny” On Matte Box

- High-End Look

- Custom Stamp Fee (One Time Cost Per Design)

- Higher Cost For Multiple Colors

- Limited Stock Colors Available Without Paying An Additional Fee

- Cannot Hold Very Fine Details

Metallic Substrate Paper

Instead of the traditional white or brown paperboard, for this option we use a white paperboard with a metallic silver film substrate. This makes any color look metallic without the use of a die and hot foil stamping.

White ink is used to hide the shine effect where desired. Any amount of colors can be printed on top of the silver substrate.

Pros

Cons

- Unlimited Color Options On The Same Box

- No Extra Setup Fees For Stamps

- Fine Details Look Sharp

- White Ink Hides The Metallic Effect Where Desired

- Limited Coating Options

- Higher Pricing Per Piece

A 360° Experience For Your Customers

Inside Printing

Printing a custom design on both the exterior and the interior of the box can add more value to your products packaging without a large investment. Interior printing allows you to continue your branding story to the inside of the box.

When the consumer opens the box, it not only reveals the great product within but beautiful colors, text and graphics that match your brand and the values your product stands for. You can use this space to write a short message, a description of your brand, instructions for using the product or even an inspiring quote.

Printing and extras for

Kraft Paperboard

Kraft boxes are an exciting product we are proud to offer and they can be very versatile. While you may think the brown color can be a limitation, we see it as an opportunity towards a different approach to design and packaging. Follow along as we describe some of the details that should be considered when designing for this paper.

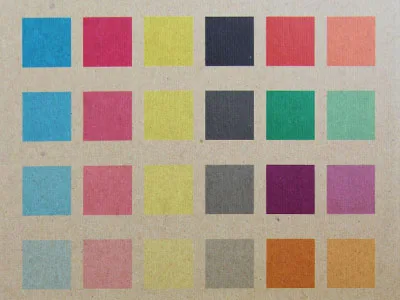

Color Appearance On Kraft Paper

Ink Colors on Kraft Paperboard

The darker paper stock changes the way colors appear on kraft paperboard, making the colors look more faded.

Ink Relativity on Kraft Paperboard

Medium to heavy ink shades tend to appear darker while light colors appear more faded on the paperboard.

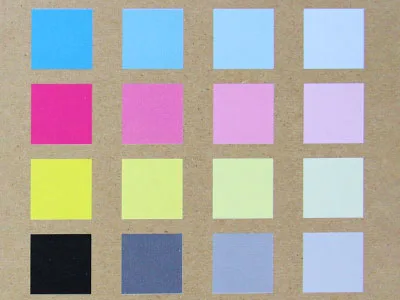

Colors on Kraft with White Ink Behind

A white ink can be laid on the paperboard to create a truer color, while keeping the textured look of the Kraft paper.

Fine Details on Kraft

Because it’s an uncoated paperboard, 100% recycled post-consumer material, the Kraft paperboard has a very textured base which cannot hold fine details as well as a coated stock.

The finest detail we recommend is 1pt. line-weight.

White Ink On Kraft Paperboard

We’ve been one of the first manufacturers in the US to provide white printing on kraft paper. This is a very distinct look and a sought-after feel in the current market.

The natural fibers in kraft paper create a textured contrast with the white ink.

Cutouts, Embellishments on Kraft

Hot foil, embossing, debossing and cutouts are available for the Kraft paperboard. We do not offer laminates or coatings on kraft paperboard.

We believe the Kraft paperboard looks fantastic all on its own.

If you’re ready to give your product the packaging it deserves without spending a fortune and waiting for months, get in touch with our team, and we’ll make it happen for you.